Why you need a CRM in the manufacturing industry

Managing sales, tracking customer interactions, and ensuring smooth communication across departments can be challenging without the right tools. This is where a Customer Relationship Management (CRM) system comes in. A well-implemented CRM can streamline operations, enhance customer satisfaction, and boost profitability.

What is CRM in the manufacturing industry?

CRM and ERP integration transfers data from your ERP system, such as inventory, product, and financial information into your CRM, while also retrieving core customer information from your CRM into your ERP. This integration is created via APIs to synchronise the two systems, leading to better decision-making, increased productivity, and a single source of truth for your business.

Here’s why manufacturers need a CRM:

1. Centralised customer data

Manufacturing companies often deal with multiple suppliers, distributors, and customers. A CRM centralises all customer information, making it easier for teams to access order history, preferences, and contact details. This ensures a seamless customer experience and allows for better decision-making.

2. Improved sales and lead management

A CRM helps track leads, automate follow-ups, and manage sales pipelines effectively. Instead of relying on spreadsheets or scattered notes, sales teams can use CRM tools to prioritise high-value prospects and close deals faster.

3. Enhanced communication and collaboration

From sales to production, multiple departments interact with customers. A CRM enables seamless communication between teams by providing a shared platform with real-time updates on customer interactions, reducing miscommunication and improving workflow efficiency – especially beneficial when integrating your ERP.

4. Better demand forecasting

Manufacturers rely on accurate demand forecasting to optimise production schedules and inventory management. A CRM collects historical data and customer trends, allowing businesses to anticipate demand and prevent overproduction or shortages.

5. Increased customer retention

Maintaining existing customers is often more cost-effective than acquiring new ones. A CRM helps manufacturers stay engaged with their customers by automating follow-ups, sending personalised offers, and providing proactive customer support.

Learn how to increase sales to existing customers in our guide.

6. Integration with other business systems

Many CRM platforms integrate with Enterprise Resource Planning (ERP) and supply chain management tools, allowing manufacturers to streamline operations. This integration enhances order tracking, inventory management, and production planning.

At enable.services, we provide integration services to connect your CRM with a system you already use in-house including ERP’s such as Epicor, Oracle Netsuite, Microsoft Business Central, SAP, and more. Customisable platforms such as SugarCRM, allow your business to integrate to any ERP system.

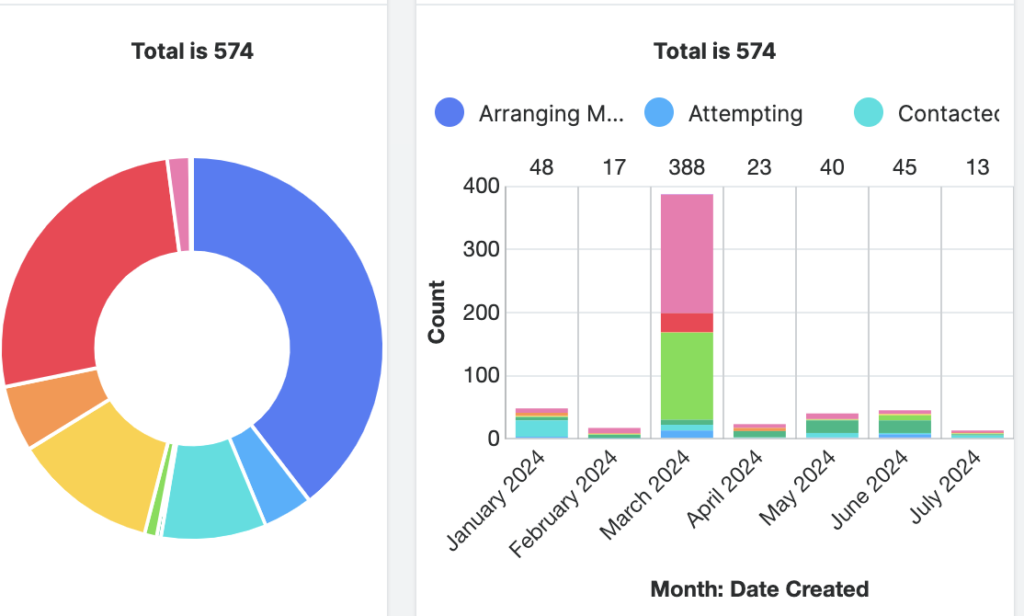

7. Data-driven decision making

With built-in analytics and reporting, a CRM provides valuable insights into customer behavior, sales performance, and market trends. This data empowers manufacturers to make informed strategic decisions that drive growth and efficiency.

Is your manufacturing business on the hunt for a brand new CRM system? Book a consultation with our experts, and we can discuss our bespoke solutions.

Extra resources:

What is SugarCRM and why should you use it?